Tissue Paper Converter-How is Tissue Paper Converting Production

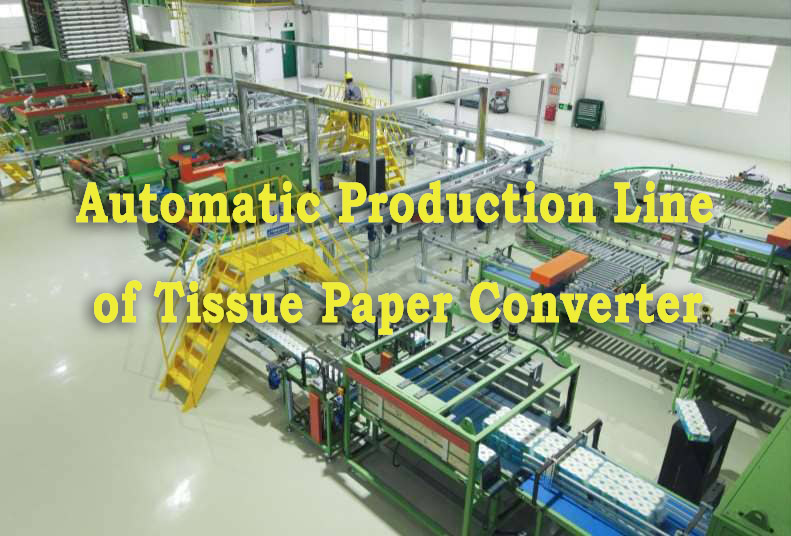

Tissue paper is a soft and thin paper product that is widely used for personal hygiene, cleaning, and wiping purposes. Tissue paper products include toilet paper, kitchen rolls, hand towels, napkins, and facial tissues. Tissue paper production involves two main stages: the formation of the tissue paper sheets from raw materials, and the converting of the tissue paper parent rolls into different finished tissue products. In this article, we will focus on the converting process and the different tissue making machines that are used.

What is tissue converting?

Converting is the process of transforming the tissue paper mother rolls into various finished tissue products, such as rolls, folded sheets, or boxes. Converting is characterized by several operations, such as unwinding, winding, embossing, lamination, perforation, cutting, packaging, and palletizing. Each operation has a specific function and impact on the final product’s properties and appearance.

Unwinding and Winding of Tissue Paper

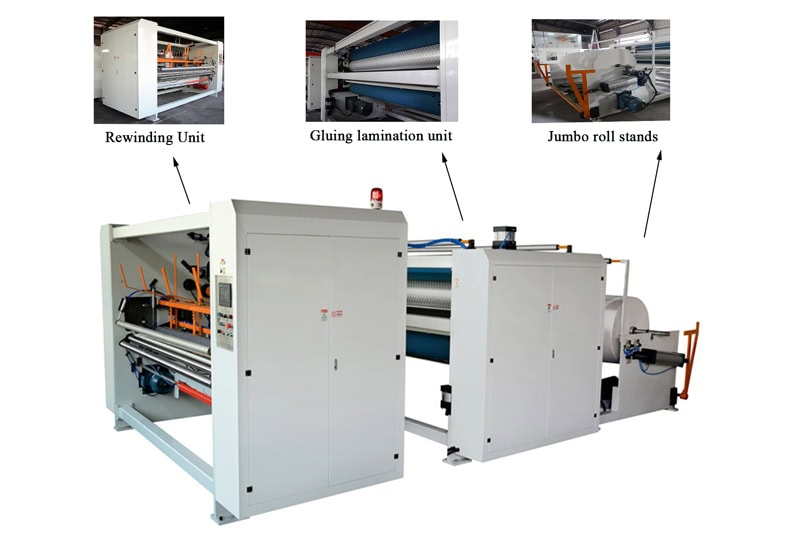

Unwinding and winding are the operations that transfer the tissue giant rolls from the paper mill to the converting plant. The tissue parent sheets comes out of the paper mill on a large roll, called the parent roll or jumbo roll, which can weigh up to several tons and have a diameter of up to 3 meters. The tissue parent roll is then transported to the converting plant, where it is unwound and fed into the converting machine. The converting machine then winds the tissue paper sheet onto smaller rolls, called logs or reels, which have a diameter of about 30 cm and a length of about 2.5 meters. The logs are then ready for further converting operations.

Embossing and Lamination of Tissue Paper

Embossing and lamination are the operations that add texture and thickness to the tissue paper reels. Embossing is the process of imprinting a pattern on the tissue parent roll by applying pressure with an embossing roller. The embossing roller can have different shapes and designs, such as dots, flowers, or logos, to create a distinctive and attractive appearance for the final product. Embossing also affects the properties of the tissue paper sheet, such as bulk, softness, absorbency, and strength. Generally, embossing increases the bulk and absorbency of the tissue paper sheet, but decreases its softness and strength.

Lamination is the process of bonding two or more plies of tissue paper sheet together with glue or mechanical pressure. Lamination can enhance the thickness, strength, and softness of the tissue paper sheet, as well as create a more uniform and smooth surface. Lamination can also be combined with embossing to create a double-sided embossed product, which has a higher quality and value.

Tissue Paper Perforation and Cutting

Perforation and cutting are the operations that divide the tissue paper mother rolls into smaller units, such as sheets or rolls. Perforation is the process of creating small holes or slits along the tissue paper sheet, which allow the user to tear off the desired amount of tissue paper easily. Perforation can be done by using a perforating blade or a laser beam, depending on the speed and accuracy required. Cutting is the process of slicing the tissue paper sheet into smaller pieces, such as napkins or facial tissue. Cutting can be done by using a rotary or a guillotine cutter, depending on the shape and size of the final tissue product.

Tissue Paper Packaging and Palletizing

Packaging and palletizing are the operations that protect and transport the finished tissue paper products. Packaging is the process of wrapping, sealing, or boxing the tissue paper products, using materials such as plastic, paper, or cardboard. Packaging can also include private labeling, printing, or coding the tissue paper products, to provide information such as brand name, product type, or expiration date. Palletizing is the process of stacking and securing the packaged tissue paper products onto a wooden or plastic pallet, which can be moved by a forklift or a truck. Palletizing can also include wrapping or strapping the pallet, to prevent the packages from falling or shifting during transportation.

What are Tissue Paper Converting Machines?

Tissue paper converting machines are the machines that perform the converting operations described above. Tissue paper converting machines can vary in size, speed, capacity, and complexity, depending on the type and quality of the final product. Tissue paper converting machines can be classified into two main categories: roll converting machines and folded converting machines.

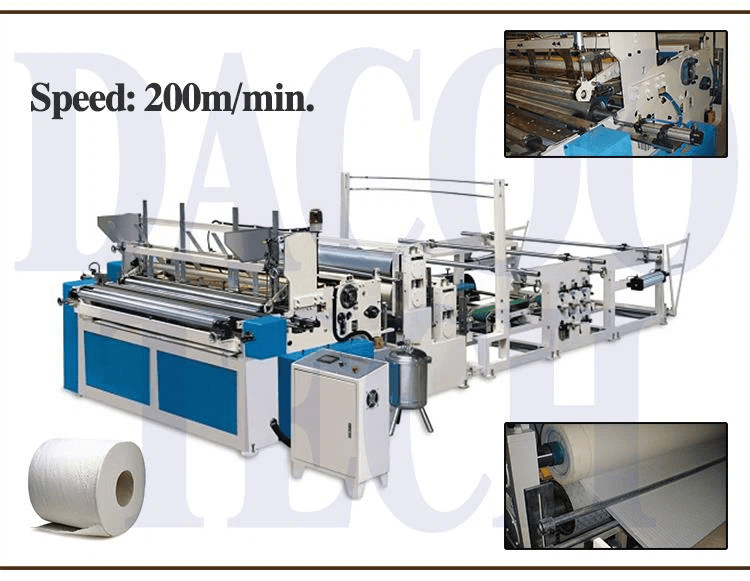

Roll Converting Machines for Tissue Paper

Roll converting machines are the machines that convert the tissue paper sheet into rolls, such as toilet paper rolls or kitchen paper rolls. Roll converting machines can perform several operations, such as unwinding, winding, embossing, lamination, perforation, cutting, and packaging. Roll converting machines can have different configurations, such as single lane or multi lane, single ply or multi ply, single embossing or double embossing, and so on. Roll converting machines can also have different features, such as automatic log change, coreless winding, glueless lamination, and so on. Roll converting machines can produce different types of rolls, such as standard rolls, jumbo rolls, mini jumbo rolls, center pull rolls, and so on.

Tissue Paper Folded Converting Machines

Folded converting machines are the machines that convert the tissue paper sheet into folded sheets, such as hand towels, napkins, or facial tissues. Folded converting machines can perform several operations, such as unwinding, embossing, lamination, cutting, folding, and packaging. Folded converting machines can have different configurations, such as single lane or multi lane, single ply or multi ply, single embossing or double embossing, and so on. Folded converting machines can also have different features, such as automatic sheet count, interfold or non-interfold, glueless lamination, and so on. Folded converting machines can produce different types of folded sheets, such as C-fold, Z-fold, V-fold, N-fold, and so on.

All in conclusion, Tissue paper converting is a complex and important process that transforms the tissue paper sheet into various finished products that are used in our daily life. Tissue paper converting involves several operations, such as unwinding, winding, embossing, lamination, perforation, cutting, packaging, and palletizing, which have a significant impact on the final product’s properties and appearance. Tissue paper converting machines are the machines that perform the converting operations, and they can vary in size, speed, capacity, and complexity, depending on the type and quality of the final product. Tissue paper converting is a challenging and rewarding industry that requires innovation and optimization to meet the ever-changing demands and preferences of the consumers.

YuanhuaPaper is a paper mill in China, have over 20 years’ experience on tissue parent rolls and finished tissue products. If you have plan to start a tissue converter business, you can tell me your details required specifications of the ttissue paper like quantity, size, ply, weight(gsm), etc? We will give you our best factory direct sale price!