Why We Need to Calculate the Estimated Weight of Tissue Paper Mother Roll?

In the tissue paper industry, understanding the weight of tissue paper mother rolls is crucial for efficient production, cost management, and quality control. Accurate weight estimation plays a pivotal role in the entire manufacturing process, from raw material procurement to final product delivery. This article explores the importance of calculating the estimated weight of tissue paper mother rolls, delving into practical applications, benefits, and industry insights that can help both newcomers and seasoned professionals optimize their operations.

What are Tissue Paper Mother Rolls?

Tissue paper mother rolls, also known as tissue parent rolls or tissue jumbo reels, are large rolls of paper used in the production of various tissue products. These rolls are created through a series of processes that transform raw pulp into finished paper, ready for converting into products like toilet paper, facial tissues, paper napkins and paper towels.

Materials and Composition

The primary material used in tissue paper mother rolls is pulp, which can be derived from wood, recycled paper, or alternative fibers. Additives such as chemicals and softeners are mixed with the pulp to enhance the paper’s softness, strength, and absorbency.

Production Process of Tissue Mother Rolls

The production process involves several stages, including pulping, bleaching, refining, and forming. The pulp is first broken down into fibers, cleaned, and treated with chemicals to achieve the desired properties. It is then pressed and dried into a continuous sheet, which is wound into large rolls.

Factors Affecting the Weight

Several factors influence the weight of tissue paper mother rolls, including the moisture content of the pulp, the type and quality of fibers used, and the presence of additives. Each of these elements can affect the final weight, making accurate estimation critical.

Importance of Accurate Weight Estimation

Accurate weight estimation of tissue mother rolls is essential for several reasons:

- Efficiency: Ensures smooth production flow and minimizes disruptions.

- Cost Control: Helps in budgeting and pricing by predicting material requirements and costs.

- Quality Control: Maintains product consistency and meets customer specifications.

Methods to Calculate Weight

There are various methods to calculate the weight of tissue mother rolls, ranging from manual techniques to advanced software tools. Both approaches have their own advantages and can be chosen based on the specific needs of the operation.

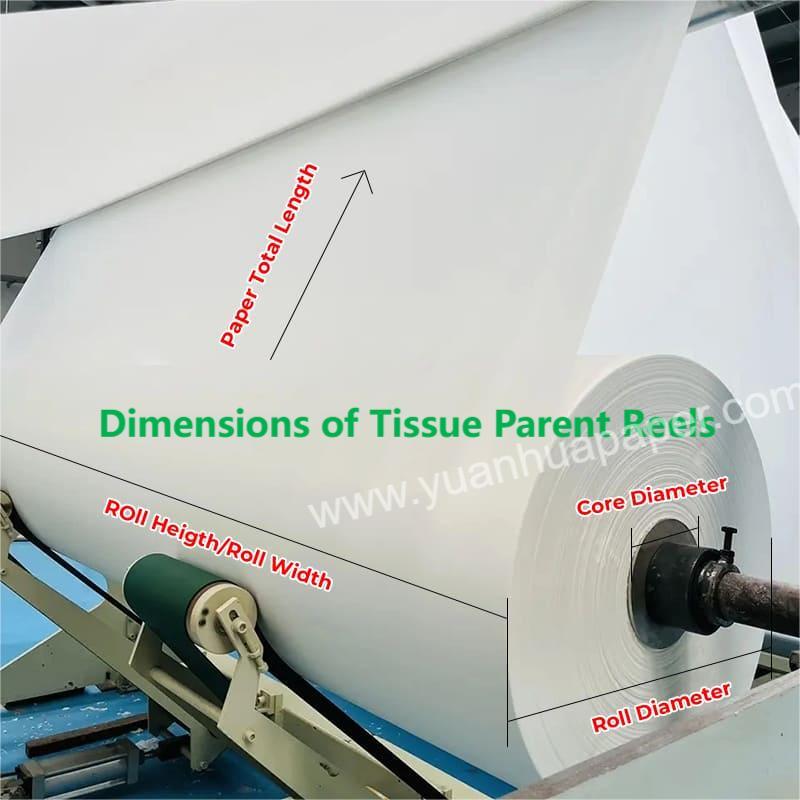

Manual Calculation Techniques

Manual calculation involves using formulas that consider the dimensions and density of the paper. This method requires precise measurements and a thorough understanding of the material properties. Here’s a step-by-step guide:

1. Measure the diameter and width of the roll.

2. Determine the basis weight of the paper.

3. Use the formula: Weight = (Diameter² – Core Diameter²) * Width * Basis Weight / Constant.

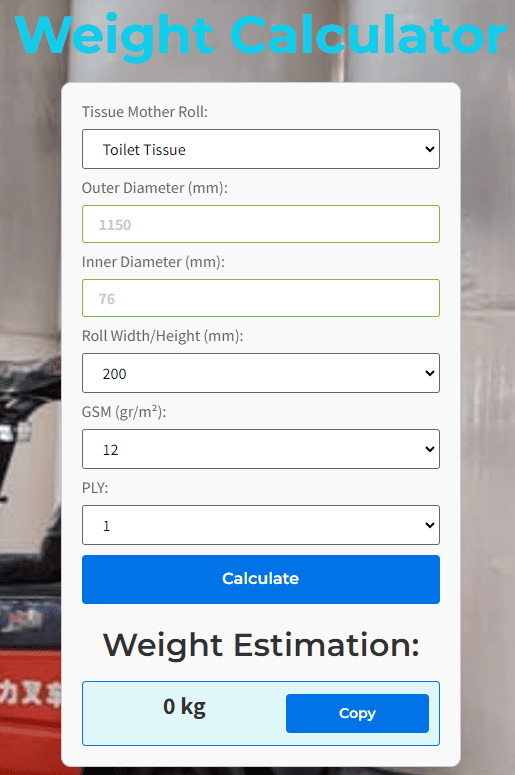

Software Tools for Weight Estimation

Several software tools are available that automate the weight estimation process. These tools can handle complex calculations and provide accurate results quickly, saving time and reducing the risk of errors. Some top software options include Paper Roll Calculator and Tissue Roll Estimator for estimated calculating. Click below online Tissue Roll Weight Estimated Calculator.

Quality Control and Consistency

Maintaining consistent weight across tissue parent rolls is vital for quality control. Variations in weight can lead to inconsistencies in the final product, affecting customer satisfaction and brand reputation.

Cost Management

Accurate weight estimation aids in effective cost management by ensuring that material usage is optimized, reducing waste, and controlling production costs. It also helps in setting competitive pricing strategies.

Inventory Management

Knowing the exact weight of tissue mother rolls helps in better inventory management. It allows for efficient storage and handling, ensuring that inventory levels are maintained at optimal levels without overstocking or shortages.

Transportation and Logistics

Accurate weight estimation is crucial for transportation and logistics. It ensures that the right amount of product is shipped, optimizing load capacities and reducing transportation costs.

Impact on Production Efficiency

Estimating the weight accurately enhances production efficiency by reducing material wastage, minimizing downtime, and ensuring that the production process of the tissue mother rolls runs smoothly.

Case Studies and Real-World Applications

Several companies have successfully implemented weight estimation practices to improve their operations. For example, a leading tissue manufacturer reduced waste by 15% and increased production efficiency by 10% through accurate weight estimation.

Challenges in Weight Estimation

Despite its importance, weight estimation can present challenges such as variability in raw materials and environmental factors. Addressing these challenges requires a combination of experience, technology, and continuous monitoring.

Technological Advancements

Advancements in technology have introduced new methods for weight estimation, such as automated sensors and real-time monitoring systems. These innovations are making the process more accurate and efficient.

Regulatory Compliance

Compliance with industry standards and regulations is essential for any tissue manufacturer. Accurate weight estimation ensures that products meet these standards, avoiding legal issues and maintaining market credibility.

Future Trends

The future of weight estimation in the tissue industry looks promising, with emerging practices and technologies aimed at further enhancing accuracy and efficiency. Innovations such as AI and machine learning are expected to play a significant role.

Conclusion

Calculating the estimated weight of tissue paper mother rolls is a fundamental aspect of the tissue industry, impacting various operational areas from production to logistics. By understanding and implementing accurate weight estimation techniques, manufacturers can achieve greater efficiency, cost control, and quality assurance. As the industry continues to evolve, staying abreast of technological advancements and best practices will be crucial for maintaining competitiveness and meeting market demands.