How To Improve The Water Absorption Of Tissue Paper From The Perspective Of Material Selection And Processing Technology?

I. Introduction

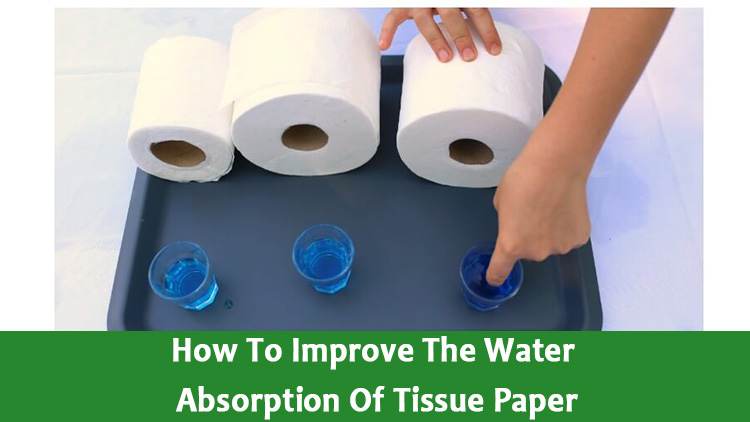

A. Importance of water absorption in tissue paper

Water absorption is a critical property of tissue paper, as it determines the effectiveness and efficiency of the product when used for cleaning or drying purposes. High water absorption ensures better performance and higher satisfaction among consumers, which ultimately leads to increased sales and a more successful tissue paper market.

B. Overview of material selection and processing technologies

The water absorption of tissue paper can be influenced by proper material selection, optimized processing technologies, and sustainable production methods. This article will explore these aspects in detail, offering insight on how to improve tissue paper water absorption.

II. Material Selection for Enhanced Water Absorption

A. Factors affecting water absorption in tissue paper materials

1. Fiber type: The cellulosic fibers used in tissue paper production directly affect the material’s ability to absorb water. Cellulose fibers contain pores that allow water to be absorbed easily.

2. Softness: Tissue paper that is soft to the touch will generally have a higher water absorption capacity.

3. Pulp quality: A higher quality pulp helps in achieving better water absorption by providing uniform and strong fibers.

B. Optimizing pulp composition

1. Hardwood and softwood pulps: Combining hardwood and softwood pulps can result in a tissue paper with improved water absorption. Hardwood fibers are thin and flexible yet durable, while softwood fibers provide strength and bulk.

2. Synthetic fibers and additives: The inclusion of synthetic fibers, such as polypropylene, or additives like wet strength resins can augment water absorption in tissue paper.

3. Alternative and sustainable fibers: Integrating alternative and sustainable fibers, such as bamboo or sugarcane, can also enhance tissue paper water absorption.

Processing Technologies to Improve Water Absorption

A. Pulping and refining processes

1. Optimizing pulping methods: Selecting the appropriate pulping method, such as chemical, mechanical, or semi-chemical, can significantly affect water absorption.

2. Mechanical refining for increased absorbency: Refining processes play a vital role in enhancing tissue paper water absorption by increasing the fiber surface area and promoting swelling properties.

B. Forming and pressing techniques

1. Wet end chemistry and formation: Optimizing the wet end chemistry can help in controlling flocculation and fines retention, thus improving water absorption.

2. Press dynamics and dewatering: Efficient pressing techniques during tissue paper production can impact the final paper’s water absorption properties by controlling fiber bonding and sheet formation.

C. Drying and creping technology

1. Through-air drying and energy efficiency: Through-air drying is an effective technique that results in increased water absorption without affecting the tissue paper’s softness.

2. Creping techniques to enhance absorption: Creping can lead to increased bulk, softness, and water absorption in tissue paper, contributing to better performance and customer satisfaction.

Multi-ply Tissue Paper and Lamination

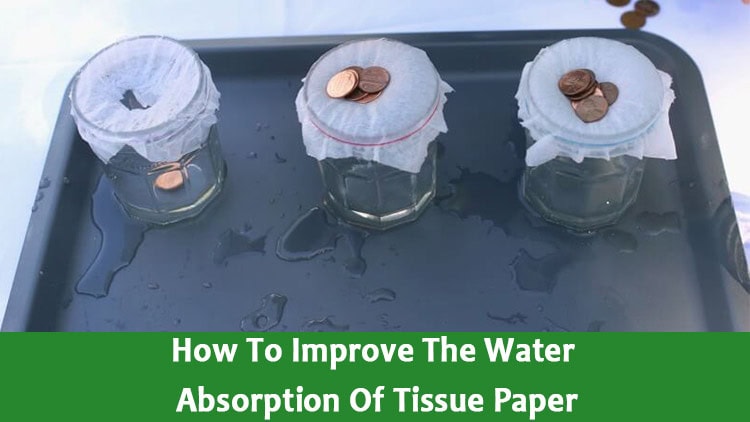

A. Advantages of multi-ply tissue paper: Multi-ply tissue paper offers enhanced strength, softness, and water absorption compared to single-ply products.

B. Lamination and embossing techniques: Lamination and embossing processes can increase the water absorption capabilities of tissue paper without sacrificing its overall strength and durability.

C. Effect on water absorption: Lamination and embossing techniques can promote water absorption in tissue paper by creating micro-cavities and adding texture, enabling the product to hold more water.

Quality Control and Evaluation of Water Absorption

A. Methods for assessing water absorption: Several tests, including the Cobb test and water retention value, can assess tissue paper’s water absorption capacity.

B. Production monitoring and feedback to optimize results: Monitoring production and conducting water absorption tests provide valuable feedback for optimizing the manufacturing process to achieve improved water absorption in tissue paper.

Sustainable Considerations in Production

A. Environmental impact of material selection and processing: Selecting sustainable materials and adopting eco-friendly processing techniques can help reduce the environmental impact of tissue paper production.

B. Strategies to minimize waste and reduce carbon footprint: Implementing strategies to minimize waste and reduce energy consumption throughout the production process can lead to a more sustainable tissue paper industry.

VII. Conclusion

A. Importance of material selection and processing technology in improving water absorption: Both material selection and processing technologies play critical roles in maximizing tissue paper’s water absorption capabilities, resulting in higher quality and more effective products.

B. Future advancements and trends in tissue paper market: As environmental concerns and consumer preferences continue to evolve, the tissue paper industry must continually innovate and adopt new strategies to improve water absorption while keeping sustainability at the forefront.