How to Start a Tissue Paper Manufacturing Business

Tissue paper is a versatile product that has many applications in personal hygiene, household cleaning, food service, and medical sectors. The demand for tissue paper is growing rapidly in developing countries due to the increasing awareness of hygiene and convenience among consumers. Tissue paper manufacturing is a profitable and low-risk business that can be started with a relatively small investment and simple machinery. In this article, we will guide you on how to prepare to set up a small tissue paper factory in a developing country. We will focus on the following points:

- Factory site selection

- Capital investment

- Equipment purchase

- Worker recruitment

Factory Site Selection

The first step to start a tissue paper manufacturing business is to find a suitable location for your factory. The location should have the following features:

- Adequate space: You will need enough space to accommodate the machinery, raw materials, finished products, and office area. The size of the space will depend on the scale of your production and the type of machinery you use. A small-scale tissue paper factory can operate in a space of about 1000 square feet.

- Easy access: You will need to transport raw materials and finished products to and from your factory. Therefore, you should choose a location that has good road connectivity and is close to your suppliers and customers. You should also consider the availability of public transport for your workers.

- Water and electricity supply: You will need a reliable and uninterrupted supply of water and electricity for your tissue paper manufacturing process. You should check the quality and cost of water and electricity in your area and ensure that they meet your requirements.

- Environmental compliance: You will need to follow the environmental regulations and standards of your country and locality. You should check the pollution control board or other authorities for the necessary permits and licenses for your factory. You should also adopt eco-friendly practices such as using recycled paper, minimizing waste, and installing proper waste disposal systems.

Capital Investment

The next step to start a tissue paper manufacturing business is to estimate the capital investment required for your factory. The capital investment will include the following costs:

- Machinery cost: This is the major cost component of your tissue paper manufacturing business. The machinery cost will depend on the type, capacity, and quality of the machines you use. There are different types of machines available for tissue paper manufacturing, such as:

- Automatic tissue paper making machine: This is a high-speed and high-efficiency machine that can produce large quantities of tissue paper in a short time. It can produce different types of tissue paper, such as toilet paper, facial tissue, napkin, paper towel, etc. It can also perform functions such as embossing, perforating, cutting, and packing. The automatic tissue paper making machine can cost between $30,000 to $80,0002.

- Semi-automatic tissue paper making machine: This is a low-speed and low-efficiency machine that can produce small quantities of tissue paper in a long time. It can produce only one type of tissue paper at a time, such as toilet paper or facial tissue. It requires manual intervention for functions such as embossing, perforating, cutting, and packing. The semi-automatic tissue paper making machine can cost between $10,000 to $20,0002.

- Manual tissue paper making machine: This is a very low-speed and low-efficiency machine that can produce very small quantities of tissue paper in a very long time. It can produce only one type of tissue paper at a time, such as toilet paper or facial tissue. It requires manual labor for all functions such as embossing, perforating, cutting, and packing. The manual tissue paper making machine can cost between $2,000 to $5,0002.

You should choose the type of machine that suits your budget, production capacity, and quality standards.

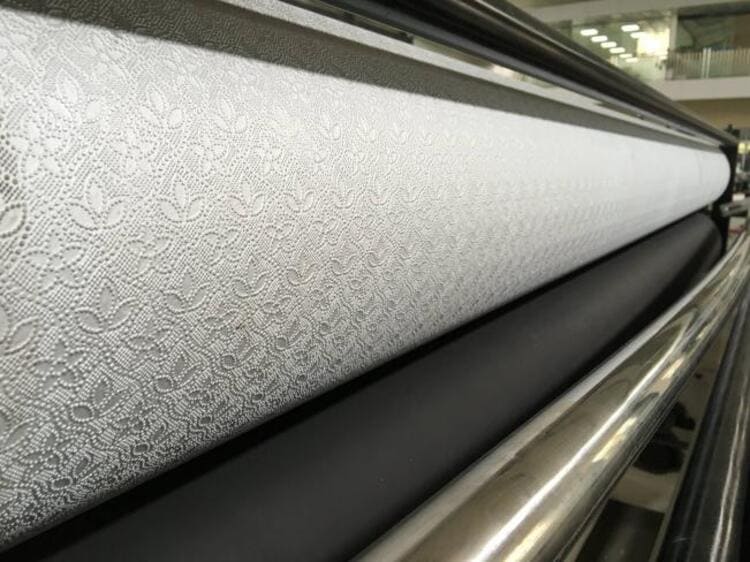

- Raw material cost: This is another major cost component of your tissue paper manufacturing business. The raw material for tissue paper manufacturing is jumbo tissue rolls, which are made from virgin wood pulp or recycled paper. The raw material cost will depend on the quality, quantity, and source of the jumbo tissue rolls. The average price of jumbo tissue rolls can range from $700 to $1,200 per ton3. You should source your raw material from reliable suppliers who can offer you good quality and competitive prices.

- Other costs: These are the minor costs that include the rent or lease of the factory space, utilities such as water and electricity bills, maintenance and repair of machinery, packaging materials such as plastic bags or boxes, transportation costs for raw materials and finished products, taxes and duties, etc. These costs will vary depending on your location, scale of production, and operational efficiency.

Equipment Purchase

The third step to start a tissue paper manufacturing business is to purchase the equipment required for your factory. The equipment will include the following items:

- Tissue paper making machine: This is the main equipment that converts the jumbo tissue rolls into the desired type of tissue paper. You should purchase the machine that matches your production capacity, quality standards, and budget. You can buy a new or used machine from a reputable manufacturer or supplier. You can also rent or lease a machine if you have a limited budget or want to test the market before investing.

- Auxiliary equipment: These are the additional equipment that support the tissue paper making machine and enhance its performance. They include items such as:

- Embossing device: This is a device that creates patterns or designs on the surface of the tissue paper, such as dots, flowers, or logos. It adds aesthetic value and softness to the tissue paper.

- Perforating device: This is a device that creates perforations or holes on the tissue paper, such as along the edges of toilet paper or napkin. It facilitates the tearing and folding of the tissue paper.

- Cutting device: This is a device that cuts the tissue paper into the required size and shape, such as rolls, sheets, or squares. It ensures uniformity and accuracy of the tissue paper.

- Packing device: This is a device that packs the tissue paper into plastic bags or boxes, either individually or in bulk. It protects the tissue paper from dust, moisture, and damage.

You should purchase the auxiliary equipment that complements your tissue paper making machine and meets your customer’s expectations.

- Testing equipment: These are the equipment that test the quality and performance of the tissue paper, such as its strength, softness, absorbency, thickness, weight, etc. They include items such as:

- Tensile tester: This is a device that measures the tensile strength or breaking force of the tissue paper, which indicates its durability and resistance to tearing.

- Softness tester: This is a device that measures the softness or smoothness of the tissue paper, which indicates its comfort and feel.

- Absorbency tester: This is a device that measures the absorbency or water retention capacity of the tissue paper, which indicates its usefulness and functionality.

- Thickness tester: This is a device that measures the thickness or caliper of the tissue paper, which indicates its density and bulkiness.

- Weight tester: This is a device that measures the weight or grammage of the tissue paper, which indicates its quality and cost.

You should purchase the testing equipment that ensures your tissue paper meets the quality standards and specifications of your market.

Worker Recruitment

The fourth step to start a tissue paper manufacturing business is to recruit workers for your factory. The number and type of workers you need will depend on the scale of your production and the type of machinery you use. Generally, you will need workers for the following functions:

- Machine operation: These are workers who operate and monitor the tissue paper making machine and auxiliary equipment. They are responsible for feeding the raw material into the machine, adjusting the settings, checking the output, and troubleshooting any problems. They should have basic technical skills and knowledge of machinery maintenance.

- Quality control: These are workers who test and inspect the quality and performance of the tissue paper using testing equipment. They are responsible for ensuring that the tissue paper meets the quality standards and specifications of your market. They should have basic analytical skills and knowledge of quality parameters.

- Packaging: These are workers who pack the tissue paper into plastic bags or boxes using packing equipment. They are responsible for ensuring that the packaging is neat, secure, and attractive. They should have basic manual skills and knowledge of packaging materials.

- Administration: These are workers who manage and supervise the overall operations of your factory. They are responsible for planning, organizing, coordinating, and controlling all aspects of your business. They should have basic managerial skills and knowledge of business administration.

You should recruit workers who are qualified, experienced, reliable, and motivated. You should also provide them with proper training, guidance, feedback, and incentives.

Conclusion

Tissue paper manufacturing is a lucrative business opportunity in developing countries where there is a growing demand for hygiene and convenience products. To start a tissue paper manufacturing business, you need to prepare well by selecting a suitable factory site, estimating your capital investment, purchasing your equipment, and recruiting your workers. By following these steps, you can set up a small tissue paper factory that can produce high-quality and profitable products for your market.

References:

1: How to Start Tissue Paper Business – Manufacturing …

2: Tissue Paper Making Business How To Start …

3: Tissue Paper Making Business Plan …