What are the Manufacturing Process of Toilet Paper Roll Converting?

Toilet paper roll converting is a sophisticated process that transforms large parent rolls of tissue paper into the smaller, consumer-friendly rolls found in households and commercial establishments. This process involves several critical steps, each designed to ensure the final product meets quality and efficiency standards. Here is a detailed overview of the manufacturing process of toilet paper roll converting:

This process involves several critical steps, each designed to ensure the final product meets quality and efficiency standards. Here is a detailed overview of the manufacturing process of toilet paper roll converting:1. Unwinding

The process begins with unwinding the large tissue parent rolls of tissue paper. These rolls, often called jumbo rolls or mother rolls, are loaded onto the unwinding machine. The machine carefully unrolls the tissue paper, ensuring it remains free of tears and maintains consistent tension.

Detailed Steps:

- Loading: The tissue parent roll is positioned onto the unwinding stand using a hydraulic lift to ensure it is securely in place.

- Tension Control: The unwinding machine is equipped with tension control systems to maintain consistent pressure on the paper, preventing tears or wrinkles.

- Alignment: Sensors and guides are used to align the paper accurately as it feeds into the next stage, ensuring the edges are straight and even.

2. Rewinding

Next, the unwound tissue paper passes through a rewinding machine. Here, the paper is tightly wound onto a core, forming the familiar toilet paper roll shape. During this step, perforations are also added to facilitate easy tearing by the end-user. The rewinding process is crucial for determining the length and density of the toilet paper rolls.Detailed Steps:

- Core Insertion: Empty cardboard cores are automatically fed into the rewinding machine.

- Paper Feeding: The tissue paper is guided onto the cores and begins to wind around them.

- Tension Adjustment: Continuous monitoring and adjustment of tension are done to ensure a tight, even roll.

- Perforation: As the paper is wound, perforation blades create small cuts at regular intervals, allowing users to tear off individual sheets easily.

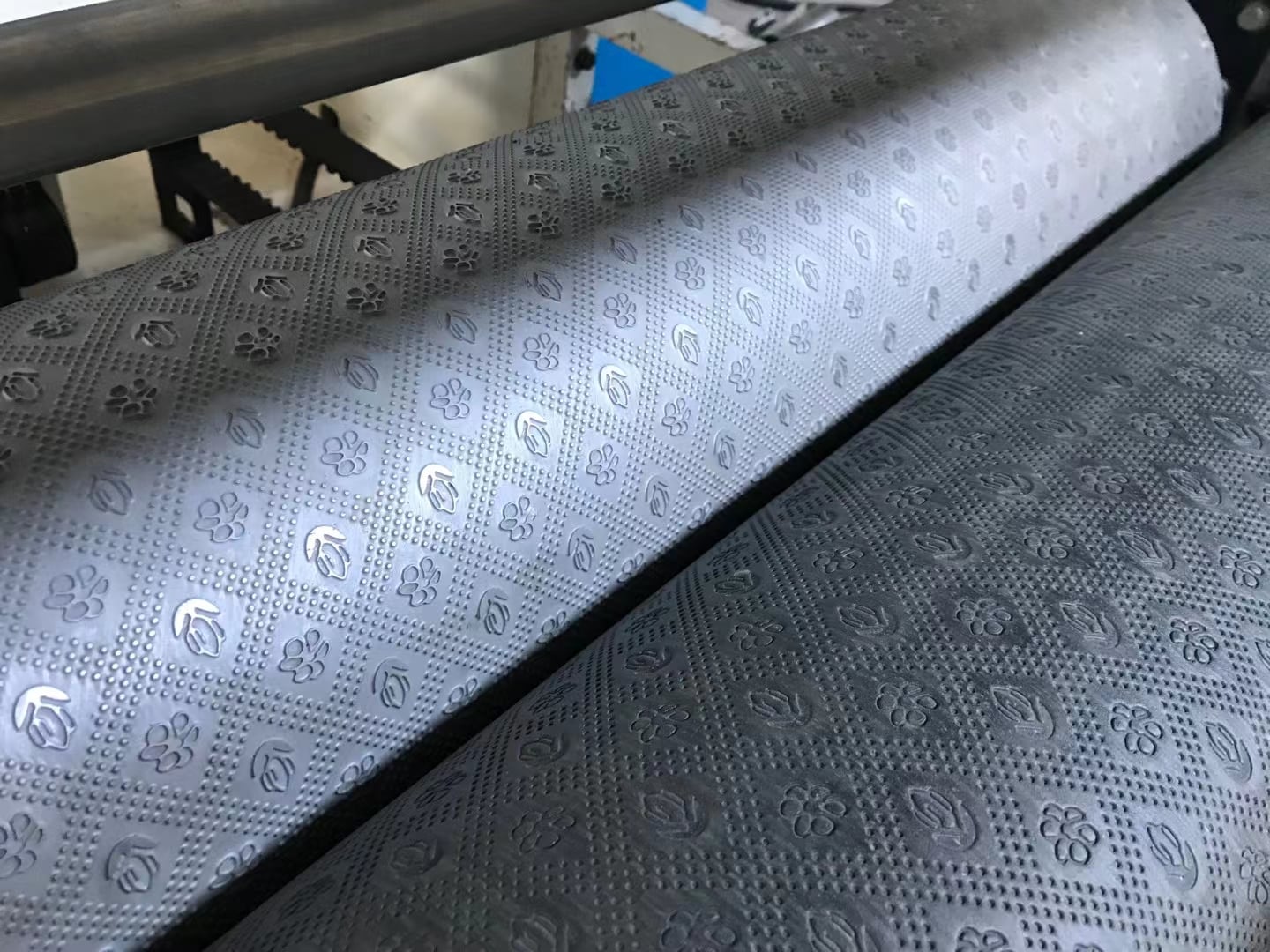

3. Embossing

Embossing is an optional but common step in toilet paper manufacturing. The tissue paper is passed through embossing rollers that imprint patterns onto the paper. These patterns not only enhance the aesthetic appeal but also improve the paper’s softness and absorbency. Embossing can include brand logos, decorative designs, or functional textures.

Detailed Steps:

- Pattern Selection: Choose the embossing pattern based on the brand’s design and functionality requirements.

- Roller Preparation: Embossing rollers are engraved with the chosen pattern and installed in the machine.

- Pressure Application: The tissue paper is passed between the embossing rollers, where precise pressure is applied to imprint the pattern onto the paper.

- Quality Check: The embossed paper is inspected for pattern consistency and depth to ensure high-quality output.

4. Laminating

In some cases, multiple layers of tissue paper are laminated together to produce a stronger, more durable product. Laminating involves bonding two or more layers of tissue with a mild adhesive, creating multi-ply toilet paper. This step is particularly important for premium quality products.

Detailed Steps:

- Layer Alignment: Two or more layers of tissue paper are aligned and fed into the laminating machine.

- Adhesive Application: A thin layer of adhesive is applied between the layers to bond them together.

- Pressing: The layers pass through pressing rollers that apply pressure to ensure a strong bond without compromising the softness of the tissue.

- Drying: The laminated paper is then dried to set the adhesive, creating a durable multi-ply product.

5. Perforating

Perforating is a critical process where small holes are punched along the width of the paper, creating tear lines. These perforations make it easy for users to tear off individual sheets. The spacing and quality of the perforations are meticulously controlled to ensure uniformity and ease of use.Detailed Steps:

- Blade Setting: Perforation blades are set to the desired spacing, typically around 4-5 inches apart.

- Roller Alignment: The paper passes through rollers equipped with the perforation blades.

- Cutting: As the paper moves, the blades create tiny cuts at regular intervals.

- Inspection: The perforations are checked for consistency to ensure that each sheet can be easily torn without tearing the entire roll.

6. Cutting

Once the toilet paper has been rewound, embossed, and perforated, it is cut to the desired roll width. High-speed cutting machines slice the large, rewound rolls into smaller, consumer-sized rolls. Precision in this step ensures that each roll is of uniform size and weight.

Detailed Steps:

- Measurement: The large rolls are measured to determine the precise cutting points.

- Cutting Mechanism: High-speed circular blades are used to cut the rolls into smaller sizes.

- Edge Trimming: The edges of the rolls are trimmed to remove any uneven or rough edges.

- Size Verification: The cut rolls are measured to ensure they meet the specified dimensions.

7. Packaging

The final stage of the converting process is packaging. The cut rolls are automatically counted and wrapped in plastic or paper packaging. This packaging protects the rolls from contamination and damage during transportation and storage. The rolls are then packed into larger boxes or pallets for distribution.Detailed Steps:

- Counting: The rolls are automatically counted and grouped according to packaging specifications.

- Wrapping: The rolls are wrapped in plastic film or paper, which is heat-sealed to provide protection.

- Labeling: Labels are applied to indicate the brand, product details, and other relevant information.

- Boxing: The wrapped rolls are packed into boxes or shrink-wrapped onto pallets for transportation.

- Sealing: The boxes or pallets are sealed to ensure the product remains secure during transit.

8. Quality Control

Throughout the entire manufacturing process, quality control checks are essential. These checks include inspecting the paper for defects, ensuring perforations are consistent, verifying the strength and softness of the tissue, and confirming the accuracy of roll dimensions. Quality control ensures that the final product meets industry standards and customer expectations.Detailed Steps:

- Visual Inspection: Regular visual inspections are conducted at various stages to identify any defects or inconsistencies.

- Tensile Testing: The strength of the paper is tested to ensure it meets required standards.

- Softness Testing: The softness of the tissue is evaluated to maintain product quality.

- Dimensional Checks: The dimensions of the rolls, including length, width, and diameter, are measured for accuracy.

- Performance Testing: Final product testing is conducted to ensure the rolls function as expected, including easy tearing at perforations and overall usability.

Conclusion

Toilet paper roll converting is a meticulous process that involves several key steps to transform large tissue rolls into the familiar products used daily. From unwinding and rewinding to embossing, perforating, and packaging, each stage is crucial in producing high-quality toilet paper rolls. Understanding this process highlights the precision and care required to deliver a product that meets both functional and aesthetic needs.FAQ

Most frequent questions and answers

Toilet paper is primarily made from either virgin pulp or recycled pulp. Virgin pulp is derived from wood fibers, typically from softwood or hardwood trees, while recycled pulp is obtained from recycled paper products. Additives such as chemicals for strength, softness, and absorbency are also used.

Embossing improves the quality of toilet paper by creating patterns that increase its softness and absorbency. The raised designs can trap air, making the paper feel softer to the touch. Additionally, embossing can add strength to the paper by interlocking the layers more effectively.

Common issues in the rewinding process include uneven tension, which can cause wrinkling or tearing of the tissue paper. Misalignment of the paper can lead to uneven rolls, and incorrect perforation settings can result in sheets that do not tear properly. Regular maintenance and calibration of the rewinding machine are essential to mitigate these issues.

Multi-ply toilet paper involves laminating two or more layers of tissue paper together, while single-ply is a single layer. The laminating process includes applying a mild adhesive between the layers and pressing them together. Multi-ply toilet paper is generally stronger, thicker, and more absorbent compared to single-ply.

Key quality control measures include:

Visual Inspections: Regularly checking for defects such as holes, tears, or discoloration.

Tensile Testing: Measuring the strength of the tissue paper.

Softness Testing: Ensuring the tissue meets softness standards.

Dimensional Checks: Verifying roll length, width, and diameter.

Performance Testing: Confirming perforations tear easily and the product functions as intended.

The perforation process creates small, evenly spaced holes that allow users to tear off individual sheets easily. Proper spacing and sharp perforation blades ensure that each sheet can be torn off smoothly without ripping the roll apart, providing a convenient and user-friendly experience.

Essential machinery for toilet paper roll converting includes:

- Unwinding Machine: For unwinding parent rolls.

- Rewinding Machine: For winding the tissue onto cores.

- Embossing Roller: For imprinting patterns.

- Laminating Machine: For bonding multiple layers.

- Perforation Blades: For creating tear lines.

- Cutting Machine: For slicing large rolls into consumer-sized rolls.

- Packaging Machine: For wrapping and boxing the final product.

Proper packaging protects toilet paper from moisture, dust, and contamination, thereby extending its shelf life. High-quality, sealed packaging ensures the product remains hygienic and intact during transportation and storage. Packaging also prevents physical damage that can occur during handling.

Current innovations in toilet paper manufacturing include:

Sustainable Materials: Using bamboo or other eco-friendly fibers.

Advanced Embossing: Creating more intricate and functional designs.

Improved Perforation Techniques: Enhancing tearability and user convenience.

Smart Packaging: Using biodegradable or recyclable materials.

Automation and AI: Implementing advanced robotics and AI for improved efficiency and quality control.

Environmental regulations impact the manufacturing process by requiring companies to adopt sustainable practices, reduce waste, and minimize emissions. This can include using recycled materials, ensuring responsible sourcing of virgin pulp, reducing water and energy consumption, and adhering to standards for chemical use. Compliance with these regulations helps protect the environment and promotes sustainable manufacturing practices.