Tissue Paper Jumbo Roll Production: A Comprehensive Guide to the Process

Tissue paper jumbo rolls, commonly used for the manufacturing of various tissue products such as facial tissues, toilet paper, and paper towels, play a vital role in our daily lives. The production of these rolls involves a series of complex processes that transform raw materials into the soft, absorbent paper we use every day. This article aims to provide a detailed overview of the production process of tissue paper jumbo rolls, highlighting the key steps and specific operations involved.

I. Raw Material Preparation

1. Pulp Selection: The primary raw material for tissue paper jumbo rolls is wood pulp, which can be sourced from hardwood or softwood trees. Pulp can be obtained through chemical or mechanical processes, with the former producing a higher quality product.

2. Pulp Preparation: The selected pulp is mixed with water and chemicals to create a slurry. This slurry undergoes refining to improve the pulp’s fiber properties, ensuring a smoother and more uniform final product.

II. Paper-making Process

1. Stock Preparation: The refined pulp slurry is further diluted with water and chemicals to achieve the desired consistency. This mixture, known as “stock,” is then screened to remove any impurities or over-sized fibers.

2. Head-box and Wire Section: The prepared stock is pumped onto a continuously moving wire mesh, where water drains through the mesh, leaving a layer of fibers on the surface. This layer of fibers forms the initial paper web.

3. Press Section: The wet paper web passes through a series of press rolls, which squeeze out excess water and consolidate the fibers. This process increases the paper’s strength and density.

4. Drying Section: The partially dried paper web is transferred to a series of heated cylinders, known as dryers. As the paper web contacts the hot surfaces, moisture evaporates, further drying the paper.

5. Grepping: To give the tissue paper its characteristic softness and flexibility, the dried paper web is scraped off the final dryer cylinder using a sharp blade, a process known as creping. This action breaks the internal fiber bonds, creating a more pliable paper product.

III. Finishing and Converting

1. Calendaring: The creped paper web is passed through a series of calendar rolls, which smooth and compress the paper to achieve the desired thickness and surface finish.

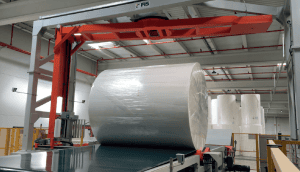

2. Rewinding: The finished tissue paper is then wound onto a large reel, creating the tissue paper jumbo roll. These jumbo rolls are typically 2-3 meters wide and can weigh up to several tons.

IV. Quality Control and Packaging

1. Quality Control: Throughout the production process, quality control measures are implemented to ensure the final product meets the required specifications. These measures include visual inspections, as well as tests for strength, absorbency, and softness.

2. Packaging: Once the tissue paper jumbo rolls pass quality control, they are wrapped in protective packaging and prepared for shipment to tissue product manufacturers.

In a Conclusion, the production of tissue paper parent rolls involves a series of intricate processes, from raw material preparation to paper-making, finishing, and quality control. Each step plays a crucial role in creating the soft, absorbent, and versatile tissue paper products we rely on in our daily lives. By understanding the production process, we can appreciate the complex engineering and craftsmanship behind these seemingly simple products.