Shandong Rizhao Pulp and Paper Enterprise Transforms into a Green Factory, Generating 1.5 Billion kWh of Electricity Annually from Waste

On June 21, the themed interview activity “Walking through the Pilot Zone to Observe Green, Low-carbon, High-quality Development” visited Shandong Rizhao to explore the production workshop of Asia Symbol (Shandong) Pulp and Paper Co., Ltd. (hereinafter referred to as Asia Symbol). The company has maximized resource utilization efficiency and reduced pollutant emissions, turning production waste such as black liquor, solid waste, and exhaust gases from the pulp and papermaking process into valuable resources, creating several “firsts” in the industry.

In the company’s exhibition hall, the reporter from Jingmu News saw various common household items, including office paper, milk cartons, sanitary products, non-woven wipes, and clothing. Their raw materials all come from the artificial plantations of Asia Symbol’s upstream enterprises. Globally, Asia Symbol’s upstream companies plant an average of 1.5 million trees daily. The wood obtained from these renewable artificial plantations can be used for pulp and paper production, paper products, and as high-end clothing fabric.

Xu Guangli, Corporate Affairs Director of Asia Symbol (Shandong) Pulp and Paper Co., Ltd., explained to the reporter that after screening and cooking, wood chips are transformed into crude pulp. The black liquor produced during this process is entirely collected and concentrated through evaporation to become biomass fuel used for power generation, producing an average of 1.5 billion kWh of electricity annually. The low-pressure steam generated after power production is reused for drying pulp or paper. The black liquor, after combustion and causticizing reactions, becomes white liquor and is recycled back into the cooking process. Through the full utilization of biomass fuel, the company can reduce carbon emissions by over 3 million tons and recover more than 1 million tons of alkali annually. The white mud produced during the causticizing process is calcined in a lime kiln, generating lime that is recycled as the initial raw material for causticizing. The company’s newly commissioned cultural paper production line directly uses liquid fresh pulp for papermaking, eliminating multiple pulp conversion processes, reducing energy and water consumption in production, and achieving the goal of increasing production without increasing pollution.

To ensure stable combustion of the odor treatment system during emergencies such as plant-wide power outages, the company invested 60 million yuan to build an odor treatment system, seamlessly connecting dual power sources, gas sources, and water sources, further improving the safety and reliability of the odor system operation. This project is the first of its kind among global pulp and paper enterprises.

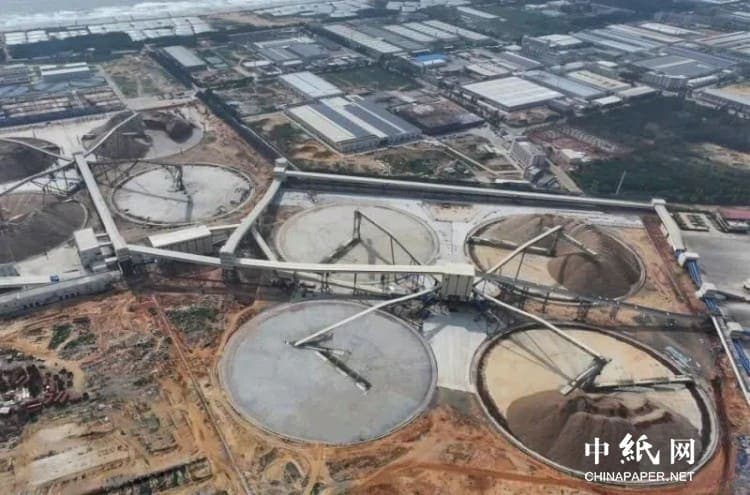

Asia Symbol is also the first in the pulp and paper industry to build a facility for retreating and reusing urban reclaimed water. The company invested nearly 70 million yuan to retreat the discharged wastewater from some of Rizhao’s domestic sewage treatment plants, processing 40,000 tons of reclaimed water daily and saving nearly 10 million cubic meters of water resources annually. The treated “new water” is used for boiler makeup water and cooling tower water replenishment.

Asia Symbol invested nearly 400 million yuan in a flue gas waste heat recovery project, which not only saves a large amount of coal and reduces flue gas moisture content and carbon dioxide emissions but also collects waste heat to provide winter heating for 6 million square meters of community residential areas. This is China’s first integrated flue gas waste heat recovery project in the paper industry, playing a leading and exemplary role in energy conservation and emission reduction for the national and global paper industry.

Currently, Asia Symbol generates about 1.5 billion kWh of electricity annually from biomass waste, achieving basic energy self-sufficiency while also reducing carbon emissions by over 3 million tons and saving 1.2 million tons of standard coal annually. After more than two decades of rapid development, Asia Symbol has become a benchmark enterprise in the pulp and paper industry for industrial upgrading, technological progress, and green development.