What is Through-Air Drying (TAD) Technology

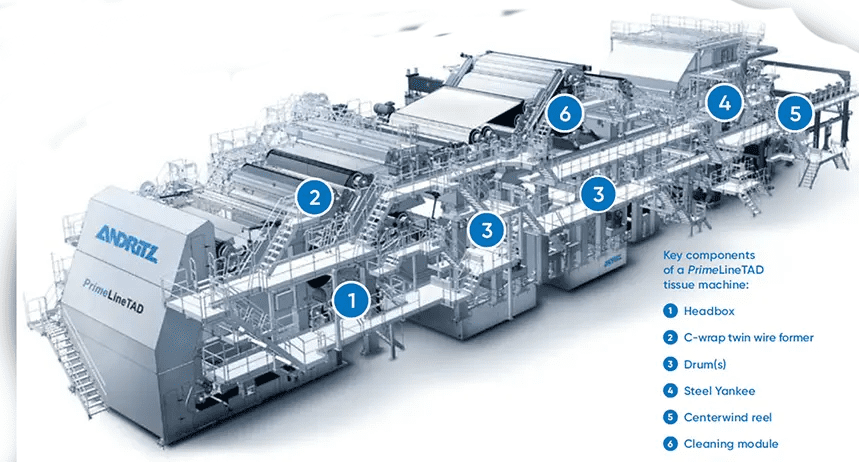

Through-Air Drying (TAD) is a widely used drying technology in the production of tissue paper. Originally pioneered by Procter & Gamble in the mid-1960s in the United States, this technique is primarily utilized to enhance the bulkiness and softness of tissue paper products. TAD technology dries the wet paper sheets directly by penetrating them with hot air without the need for pressing, achieving high bulk and absorbency.

Characteristics of TAD Technology

TAD technology is characterized by:

- Increased Bulkiness: Paper produced using TAD technology has higher bulk, which translates into greater volume and a softer feel.

- Enhanced Absorbency: TAD paper exhibits superior absorbency compared to conventional paper, making it ideal for products requiring high absorbency like facial tissues and kitchen towels.

- Eco-Friendly: Made from plant fibers, TAD paper is biodegradable and environmentally friendly.

- High Processability: TAD paper is easy to process and can be embossed with various 3D patterns, developing more product types and enhancing the competitive edge of paper companies.

Challenges of TAD Technology

Despite its advantages, TAD technology faces several challenges:

- High Energy Consumption: Achieving the drying effect requires higher air pressure, temperature, and volume, thus necessitating more powerful air systems and leading to higher energy consumption.

- Gas Resource Dependency: Most TAD drying processes use gas as the primary energy source, potentially increasing operational costs and imposing stricter site selection criteria.

- Maintenance Complexity: The structure of TAD paper machines is relatively complex, demanding high skill levels from operators and posing greater maintenance and management challenges.

Applications and Development of TAD Technology

TAD technology is not only used in high-end facial and kitchen towels but is also gradually being applied to other paper products for daily use. With deeper understanding of the TAD concept and mimetic R&D in the related equipment industry, more innovative models and techniques are expected to emerge.

Conclusion

Despite some challenges, TAD technology remains an effective method for producing tissue paper with high bulk and absorbency, which continues to be welcomed in the market. As the technology evolves, its application is likely to expand further.

Strategies to Optimize TAD Technology

To reduce energy consumption and enhance production efficiency, consider the following strategies:

1. Process Analysis and Simplification: Analyze the production process in detail to identify and eliminate unnecessary steps, reducing production time and costs.

2. Advanced Equipment: Incorporate modern, high-precision equipment to significantly boost efficiency, such as more effective drying systems and automated controls.

3. Optimized Scheduling: Arrange tasks for workers and machines to avoid bottlenecks and waste, ensuring effective resource utilization.

4. Quality Management System: Establish a robust quality control system to minimize rework and waste from quality failures.

5. Increased Automation: Implement automated systems to reduce human error, enhancing both efficiency and consistency.

6. Efficient Use of Energy and Resources: Explore solutions that use less energy, such as efficient energy management systems or renewable energy sources.

7. Continuous Improvement and Innovation: Encourage innovative thinking among employees to continuously improve production processes.

8. Data Analysis and Feedback: Utilize data analytics to monitor production and quickly adjust to issues, ensuring maximum efficiency.

The Mechanism of TAD Technology in Enhancing Softness and Absorbency

TAD technology improves paper softness and absorbency through the following mechanisms:

1. Through-Air Drying: Directly exposing the wet paper sheets to hot air not only transfers heat but also removes moisture quickly, reducing friction and wear from drying drums and thus enhancing softness.

2. Maintaining High Bulk: TAD maintains high void volume in the paper during drying, increasing absorbency and allowing for specific patterning to further enhance softness.

3. Reduced Mechanical Compression: By avoiding mechanical pressing in the drying process, TAD preserves the natural structure and softness of the paper.

4. Enhanced Production Efficiency: TAD maintains high-quality paper production at faster speeds, reducing energy consumption and production costs.

5. Optimized Drying Conditions: TAD allows precise control over drying conditions like temperature, humidity, and duration to ensure optimal absorbency and softness.

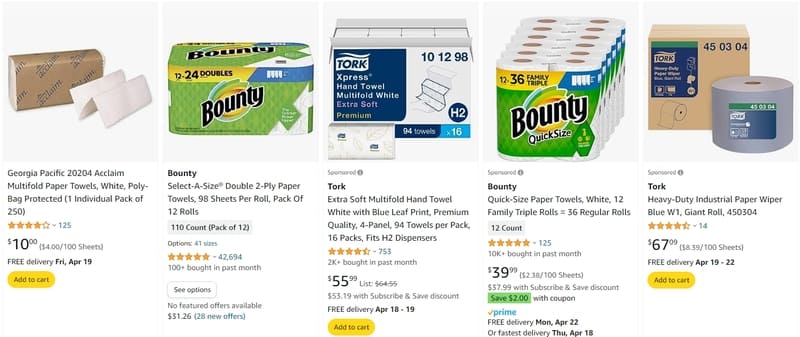

Impact of TAD Technology on the Tissue Paper Market

TAD technology has significantly enhanced the softness and absorbency of tissue paper, which will have a major impact on the future of the tissue paper market. Here are some key points illustrating how TAD technology is shaping market trends:

1. Quality Upgrades: TAD technology enables the production of higher-quality tissue papers, prompting the industry to move towards more premium products. For example, the “Cottontouch” series by C&S Paper, which uses TAD technology, offers twice the bulk and twelve times the absorbency of traditional paper, greatly enhancing comfort and utility.

2. Shifts in Market Demand: As consumer expectations for quality increase, the market will focus more on the quality and functionality of products. This means consumers are likely to prefer brands that offer higher added value, such as those using 100% virgin wood pulp.

3. Innovation and Material Choices: TAD technology may drive innovation in the tissue paper industry and affect raw material choices. Virgin wood pulp, known for its purity and natural properties, is becoming increasingly popular among consumers, likely boosting demand for this material.

4. Enhanced Environmental Awareness: TAD technology does not require chemical additives, aligning with growing consumer interest in sustainability. The future may see more eco-friendly products in the market to meet this rising demand.

5. Increased Brand Influence: As TAD technology develops, leading brands like C&S Paper could enhance their market position by offering high-quality products, setting industry standards, and promoting superior products.

6. Consumer Education: Given the presence of varied quality in tissue products on the market, brands may need to invest more in consumer education. This might include transparent disclosure of product ingredients, production processes, and certification standards.

In summary, the development of TAD technology is likely to drive the tissue paper market towards higher quality, greater environmental consciousness, and technological innovation. Brands will need to adapt to these changes to meet growing consumer needs and expectations.

| Gold Related organizations | |

| Name of Association | Organizational Overview |

| Procter①②3①② | American multinational consumer goods company pioneered the application of TAD technology in hygiene paper production |

| ANDRITZ Group | International technology group, providing hot air penetration bonding technology in Solutions for the paper and industrial sectors within |

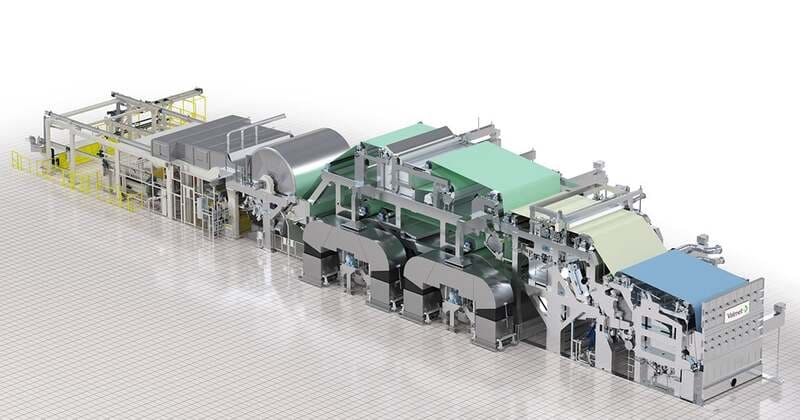

| Valmet | A global leader in automation and automation for the pulp, paper and energy industries service provider |

| Voith Group | Provide solutions for the papermaking, packaging, printing and household paper industries Programs and Services |

Questions Related to TAD Technology:

- How does TAD technology achieve efficient drying of paper?

- How to choose the right through-air drying technology to meet various tissue paper needs?

- What significant improvements do new steam-saving TAD machines offer over traditional equipment?

| event name | event time | event description |

| First application of TAD technology | 1960s | TAD (Through-Air Drying)The technology was used by Procter & Gamble in the United States for the first time for toilet paper production, improving the quality of paper Softness and absorbency |

| TAD technical paper machine configuration release | 2006 | Research on TAD technology paper machine configuration Published, introducing TAD technology in textiles and nonwovens industry applications |

How do you make the best tissue paper products? You start with the best tissue paper cellules material. That’s why we use 100% virgin wood pulp to make our tissue paper JUMBO reels, which are the finest and most hygienic tissue paper base. You can use our TAD tissue paper parent reels to produce napkins and hand towels of any quality and quantity. Order now and get a free sample!