Main Tree Species Used in Virgin Wood Pulp for Toilet Paper Production and Their Unique Characteristics

Toilet paper is one of the most essential and widely used products in our daily lives. It is estimated that the global consumption of toilet paper was about 22.5 million tonnes in 2019, equivalent to 27,000 trees per day. However, not all toilet paper is made from recycled materials. In fact, a large proportion of toilet paper is made from virgin wood pulp, which is derived from trees that have never been used before in any manufacturing process. This article will explore the importance and implications of using virgin wood pulp for toilet paper production, as well as the main tree species used and their unique characteristics.

Understanding Virgin Wood Pulp

Virgin wood pulp is a term used to describe wood fiber that is sourced from trees that have never been used in any manufacturing process. It is also known as “pure” or “fresh” pulp, as it has not been recycled or re-pulped. Virgin wood pulp is commonly used in various industries such as paper, packaging, and hygiene products, where it is valued for its superior quality and strength.

The process of making virgin wood pulp involves several steps. Firstly, the wood chips are debarked and chipped into small pieces. Then, the wood chips are cooked with chemicals such as sodium hydroxide and sodium sulfide in a large pressure vessel called a digester. This process breaks down the lignin and other substances in the wood, leaving behind cellulose fibers. Once the wood chips have been broken down, the resulting pulp is washed and screened to remove any impurities. It is then bleached with hydrogen peroxide or chlorine dioxide to achieve the desired brightness level. Finally, the pulp is dried and pressed into sheets or rolls, ready for use in various products.

There are several types of virgin wood pulp, including softwood pulp, hardwood pulp, and bleached pulp. Softwood pulp is made from coniferous trees, such as pine and spruce, and is commonly used in the production of paper products. Hardwood pulp is made from deciduous trees, such as oak and maple, and is often used in the production of tissue products. Bleached pulp is a type of pulp that has undergone an additional bleaching process to remove any remaining lignin and increase its whiteness.

Main Tree Species Used in Virgin Wood Pulp Production

The choice of tree species used in virgin wood pulp production depends on several factors, such as availability, cost, quality, and environmental impact. Generally speaking, there are two main categories of tree species used: softwood trees and hardwood trees.

Softwood Trees

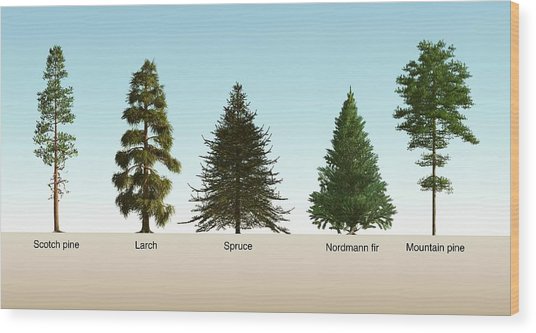

Softwood trees are trees that have needle- or scale-like leaves that usually remain on the tree throughout the year. They are also known as evergreens or conifers. Softwood trees are typically faster-growing than hardwood trees and have lower densities and lighter colors. Softwood trees account for about 80% of the world’s production of virgin wood pulp.

Some of the common softwood trees used in toilet paper production are:

- Pine: Pine trees are widely distributed across the globe and belong to the Pinaceae family. They have long, straight needles and produce cones that contain seeds. Pine trees are highly valued for their high-quality lumber, pulp, and resin. Pine lumber is often used in construction, flooring, furniture, and other woodworking applications. Pine pulp is used to make various types of paper products, such as newsprint, printing paper, packaging paper, and tissue paper. Pine pulp has high strength, brightness, and softness properties that make it suitable for toilet paper production.

- Spruce: Spruce trees are also members of the Pinaceae family and are found throughout North America, Europe, and Asia. They have short, sharp needles and produce small cones that contain seeds. Spruce trees are mainly used for timber production, especially for building houses and furniture. Spruce pulp is also widely used in the paper industry, especially for producing newsprint, printing paper, packaging paper, and tissue paper. Spruce pulp has similar properties to pine pulp but tends to be less bright and more coarse.

- Fir: Fir trees are another type of coniferous tree that belong to the Pinaceae family. They have flat needles that grow directly from the twig and produce upright cones that shed their scales when mature. Fir trees are mainly grown for ornamental purposes or as Christmas trees. Fir pulp is also used in the paper industry but less frequently than pine or spruce pulp. Fir pulp has lower strength and brightness than pine or spruce pulp but has higher softness and bulkiness properties that make it suitable for toilet paper production.

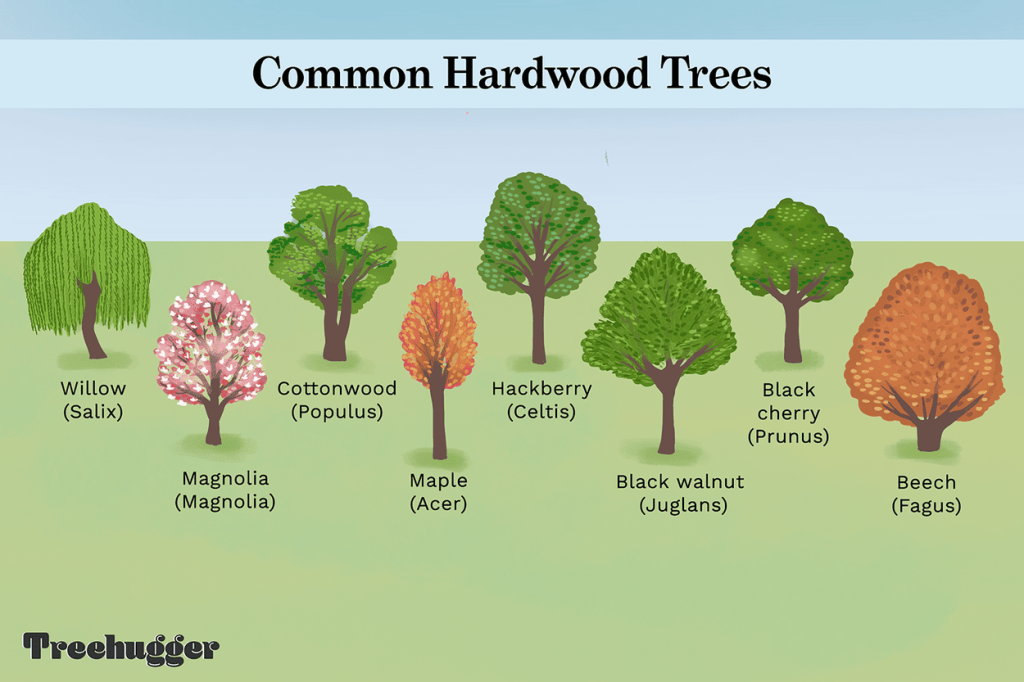

Hardwood Trees

Hardwood trees are trees that have broad leaves that usually shed during certain seasons of the year. They are also known as deciduous or angiosperm trees. Hardwood trees are typically slower-growing than softwood trees and have higher densities and darker colors. Hardwood trees account for about 20% of the world’s production of virgin wood pulp.

Some of the common hardwood trees used in toilet paper production are:

- Eucalyptus: Eucalyptus trees are native to Australia but have been widely planted in other parts of the world, especially in tropical and subtropical regions. They belong to the Myrtaceae family and have leathery leaves that contain oil glands. Eucalyptus trees are mainly used for timber production, pulp production, and oil extraction. Eucalyptus pulp is one of the most widely used hardwood pulps in the paper industry, especially for producing tissue paper, printing paper, and packaging paper. Eucalyptus pulp has high strength, brightness, and smoothness properties that make it suitable for toilet paper production.

- Birch: Birch trees are found throughout the northern hemisphere and belong to the Betulaceae family. They have thin, layered bark with lenticels or raised porous lines. Birch trees are mainly used for timber production, furniture making, and plywood manufacturing. Birch pulp is also used in the paper industry, especially for producing tissue paper, printing paper, and packaging paper. Birch pulp has lower strength and brightness than eucalyptus pulp but has higher softness and bulkiness properties that make it suitable for toilet paper production.

- Acacia: Acacia trees are native to Africa, Australia, and Asia but have been introduced to other regions as well. They belong to the Fabaceae family and have compound leaves that consist of many small leaflets. Acacia trees are mainly used for timber production, charcoal production, and gum extraction. Acacia pulp is also used in the paper industry, especially for producing tissue paper, printing paper, and packaging paper. Acacia pulp has similar properties to eucalyptus pulp but tends to be less bright and more yellowish.

Differences in Tree Species Used

The choice of tree species used in virgin wood pulp production affects the quality and characteristics of the final toilet paper product. Some of the main differences between softwood and hardwood trees in virgin pulp production are:

- Fiber length: Softwood trees have longer fibers than hardwood trees, which means they can form stronger bonds with each other and create a more durable paper product. However, longer fibers also make the paper product less flexible and more prone to cracking or tearing. Hardwood trees have shorter fibers than softwood trees, which means they can form weaker bonds with each other and create a less durable paper product. However, shorter fibers also make the paper product more flexible and less prone to cracking or tearing.

- Fiber width: Softwood trees have thinner fibers than hardwood trees, which means they can create a smoother and more uniform paper product. However, thinner fibers also make the paper product less absorbent and more translucent. Hardwood trees have thicker fibers than softwood trees, which means they can create a rougher and more variable paper product. However, thicker fibers also make the paper product more absorbent and less translucent.

- Fiber color: Softwood trees have lighter-colored fibers than hardwood trees, which means they can create a brighter and whiter paper product without much bleaching. However, lighter-colored fibers also make the paper product more susceptible to yellowing or fading over time. Hardwood trees have darker-colored fibers than softwood trees, which means they can create a darker and duller paper product that requires more bleaching. However, darker-colored fibers also make the paper product more resistant to yellowing or fading over time.

Environmental Implications

The production of virgin wood pulp for toilet paper has significant environmental implications that need to be considered and addressed. Some of the main environmental impacts are:

- Deforestation: The harvesting of trees for virgin wood pulp production contributes to deforestation and forest degradation around the world, especially in tropical and subtropical regions where most of the fast-growing tree species are found. Deforestation leads to biodiversity loss, soil erosion, water pollution, climate change, and social conflicts.

- Greenhouse gas emissions: The conversion of wood to virgin wood pulp involves various chemical processes that emit greenhouse gases such as carbon dioxide, methane, nitrous oxide, and sulfur dioxide into the atmosphere. These gases contribute to global warming and climate change by trapping heat in the earth’s system.

- Water consumption: The production of virgin wood pulp requires large amounts of water for cooking, washing, bleaching, and drying processes. This water consumption depletes freshwater resources and affects aquatic ecosystems.

Water pollution: The wastewater generated from virgin wood pulp production contains various pollutants such as organic matter, suspended solids, nutrients, metals, chlorinated compounds, dioxins, furans, and other toxic substances that are discharged into rivers or lakes or treated inadequately before disposal. This water pollution affects aquatic life and human health and well-being.

Conclusion

The production of toilet paper from virgin wood pulp involves the use of various tree species that have different characteristics and properties. The choice of tree species affects the quality, performance, and environmental impact of the final toilet paper product. Some of the main tree species used are pine, spruce, fir, eucalyptus, birch, and acacia. Each of these tree species has unique advantages and disadvantages in terms of fiber length, width, color, strength, softness, brightness, and absorbency. The production of virgin wood pulp also has significant environmental implications, such as deforestation, greenhouse gas emissions, water consumption, and water pollution. Therefore, it is important to adopt sustainable practices and policies to ensure the conservation and management of forest resources and the protection of the environment.

Some of the future trends in sustainable toilet paper production include:

- Increasing the use of recycled or alternative fibers: Recycled fibers are fibers that have been recovered from waste paper or other sources and reprocessed into new paper products. Alternative fibers are fibers that are derived from non-wood sources such as bamboo, hemp, cotton, or agricultural residues. These fibers can reduce the demand for virgin wood pulp and save trees, water, energy, and chemicals. However, they may also have lower quality or higher costs than virgin wood pulp.

- Improving the efficiency and cleanliness of pulp production processes: Pulp production processes can be improved by using less water, energy, and chemicals; reducing emissions and wastes; increasing recycling and reuse; and adopting best available technologies and practices. These improvements can enhance the environmental performance and economic viability of pulp production.

- Promoting consumer awareness and responsibility: Consumer awareness and responsibility can be promoted by providing clear and accurate information on the environmental impacts of toilet paper products; encouraging consumers to choose eco-friendly products that have lower environmental footprints; and educating consumers on how to use toilet paper wisely and responsibly. These actions can help consumers make informed decisions and reduce their environmental impacts.

Toilet paper is a product that we use every day but often take for granted. By understanding the importance and implications of using virgin wood pulp for toilet paper production, as well as the main tree species used and their unique characteristics, we can appreciate the value and complexity of this product and its production process. We can also take action to support sustainable toilet paper production and consumption that can benefit both people and the planet.