Why Is Paper Density Very Important for Tissue Paper Production?

In the tissue paper industry, the density of paper is a critical factor that directly influences the quality and performance of the final product. Understanding and managing paper density is essential for manufacturers aiming to produce top-quality tissue paper that meets both consumer demands and industry standards.

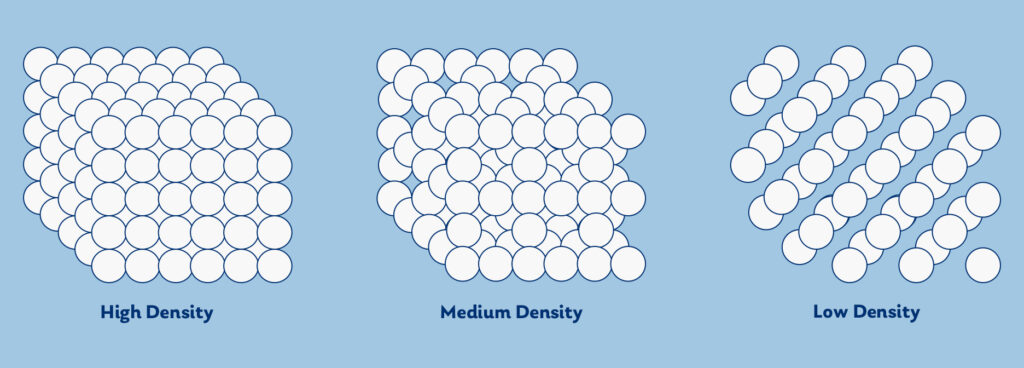

Understanding Paper Density

Paper density is defined as the mass of paper per unit volume, typically measured in grams per cubic centimeter (g/cm³). It serves as a crucial indicator of the paper’s structure and characteristics, impacting various properties such as strength, softness, absorbency, and overall usability.

Impact on Product Quality

- Softness and Comfort

For products like facial tissues and toilet paper, softness and comfort are key selling points. Generally, a lower density results in a softer and more comfortable tissue paper. By precisely controlling the density, manufacturers can create a plush, gentle product that enhances the user experience.

- Absorbency and Strength

The density of tissue paper significantly affects its absorbency and strength. Higher density papers tend to be stronger and can hold more liquid without disintegrating, which is vital for products like paper towels and kitchen rolls. These products require a balance between durability and high absorbency to perform effectively.

Production Efficiency

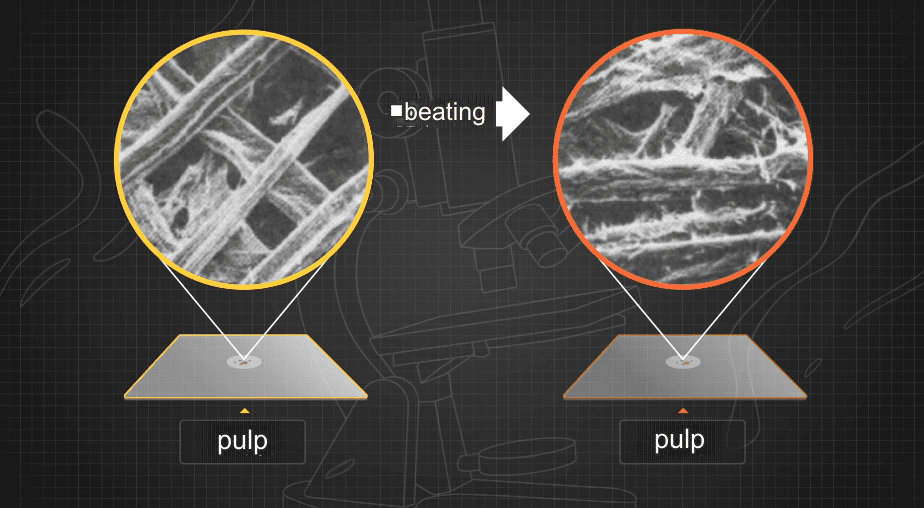

- Raw Material Utilization

Optimizing paper density allows for more efficient use of raw materials. Controlling the density ensures that manufacturers can produce the desired volume of tissue paper using fewer materials, thus reducing waste and lowering production costs. This efficiency is especially beneficial in large-scale production settings.

- Energy Consumption

Lower density papers often require less drying time and energy during the production process. By optimizing density, manufacturers can reduce energy consumption, which lowers operational costs and supports environmental sustainability initiatives. This is a key consideration in today’s environmentally conscious market.

Consistency and Quality Control

Maintaining a consistent paper density is vital for quality control. Variations in density can lead to inconsistencies in the final product, affecting its performance and consumer satisfaction. By closely monitoring and controlling density parameters, manufacturers can ensure a uniform product that meets stringent quality standards.

Competitive Advantage

In a competitive market, the ability to produce high-quality tissue paper with optimal density parameters can provide a significant edge. Consumers increasingly demand products that offer superior softness, strength, and absorbency. Meeting these demands through precise density control can enhance brand reputation and foster customer loyalty.

Country-Specific Requirements for Paper Density

Different countries have varying preferences and requirements for tissue paper density, influenced by cultural factors, consumer habits, and regulatory standards. Understanding these regional differences is crucial for manufacturers looking to compete in the global market.

- United States

In the United States, consumers prioritize softness and comfort in tissue products. This preference drives a demand for lower-density papers, especially for facial tissues and toilet paper. The focus is on creating a luxurious feel, which necessitates careful control of paper density to achieve the desired softness without compromising strength.

- European Union

European consumers often value environmental sustainability alongside product quality. There is a preference for tissue papers that balance softness with eco-friendly features, such as recycled content. This requires manufacturers to produce lower-density papers that maintain softness and comfort while meeting stringent environmental standards.

- Asia-Pacific

In the Asia-Pacific region, especially in countries like Japan and South Korea, there is a strong emphasis on product performance. Consumers expect tissue papers that are both strong and absorbent. This leads to a preference for medium to high-density papers that provide durability and high absorbency without sacrificing softness.

- Middle East

The Middle East market often demands high-quality, luxurious tissue paper products. Consumers in this region prefer lower-density papers for their softness and comfort, similar to preferences in the United States. However, there is also a growing demand for premium, highly absorbent products, requiring a balance in density control.

- Africa

In Africa, cost-effectiveness and practicality are key factors driving consumer preferences. There is a demand for durable, high-absorbency products that can be produced at a lower cost. This often translates to a preference for higher-density papers that offer strength and functionality.

Conclusion

In conclusion, paper density is a crucial parameter in tissue paper production that affects product quality, production efficiency, and overall consistency. By understanding and controlling density, manufacturers can produce superior tissue paper products that meet consumer expectations and excel in the marketplace. Focusing on density not only enhances product performance but also contributes to cost efficiency and sustainability in the tissue paper industry.

Understanding the importance of paper density and its impact on various aspects of tissue paper production helps manufacturers deliver high-quality products while maintaining operational efficiency and sustainability. Recognizing and adapting to the different density preferences across various regions further enables manufacturers to meet global consumer demands effectively.

RFQ: Tissue Paper Density

1. Q: What is the density of tissue paper in kg/m³?

A: The density of tissue paper typically ranges from 20 to 70 kg/m³.

2. Q: What is the density of a paper?

A: The density of standard paper varies widely, usually between 600 and 1200 kg/m³, depending on the type and intended use of the paper.

3. Q: What is the density of a toilet paper roll?

A: The density of toilet paper rolls generally ranges from 50 to 80 kg/m³.

4. Q: How dense is tissue paper?

A: Tissue paper usually has a density between 20 to 70 kg/m³.

5. Q: What is the density of paper weight?

A: Paper weight, often measured in grams per square meter (gsm), translates to a density typically between 600 and 1200 kg/m³ for standard paper types.